PROJECT 11

December 2003

RESTORING A POWERDRIVE MOTOR

Recently while building the Blaw Know bulldozer, modelplans number 57, I needed the use of the powerdrive motor.

The powerdrive motor I have does not run smoothly when engaged in ratios 32:1 and 60:1.

I suspected broken teeth on those gears.

I also have a 6-Ratio Gearbox in good working order that is exactly the same as the powerdrive, minus the motor.

I decided to do a transplant of the gears into the powerdrive unit, as I am more likely to use it as opposed to the 6-Ratio

Gearbox which I have had for years and never used.

The patient, a 6-speed powerdrive.

The donor, a 6-ratio Gearbox.

Upon examining the gearboxes, I discovered that protruding lugs from the rear casing

pass through flanges on the front casing and are melted to join the two halves.

To

split the casing you have to drill out the lugs.

I

drilled of only enough to get the cases to split, as I wanted to keep enough

material to force a join later.

On the left you can see the lugs which are melted to the flange to keep the gearbox together.

On

the right you can see where I have drilled the lugs out.

The split case. In the middle bottom of the picture, resting on the divider plate you can

see one of the teeth that had sheared off of the gear.

The

old, damaged gears are at the top. The donor gears in perfect condition are

ready to be greased and placed.

How

it works:

In

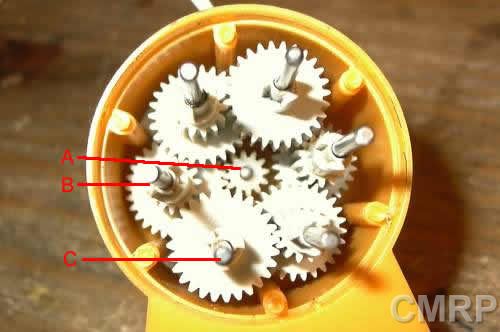

the picture above, you can see the new donor gears in position.

The

gear (B) in the 9 o'clock position engages with the

pinion (A) on the motor shaft. This

is the only gear that engages with the motor pinion.

This

gives a ratio of 3:1.

Each

pinion engages with the next gear from the 3:1 ratio clockwise, giving increased

reduction all the way up to 60:1 at the 6 o’clock

position (C). The 3:1

gears (B) and 60:1

gears (C) do not engage.

All of the gears are in constant mesh, but do not engage the final output shaft (Not inserted in this view).

To

use a ratio, you pull down the black tab on the front casing, which pulls down a

transfer pinion which engages the dog clutch at the end of each shaft.

The

transfer pinion engages the pinion on the output shaft giving final drive.

The

divider plate and front casing have a locating tab on the rear casing, so they

can only go on one way making reassembly really easy.

I

placed a drop of plastic glue in the holes where the tabs used to be and left it

to dry.

I

did this instead of putting glue under the flanges in case I need to split the

gearbox again.

I

gave it a test run under load, and everything runs smoothly and the two cases

hold together well.

As

for the donor… I placed the damages gears and taped the gearbox together. Who

knows what use it will offer in the future?