PROJECT 8

March 2003

MAKING ELEKTRIKIT PIVOT BOLTS AND ELEKTRIKIT CONTACT SCREWS

Contact Screws

CONTACT SCREWS

The Elektrikit Contact Screw is a 3/8" long bolt. The thread under the head is removed to ID it as a Contact Screw.

The end of the bolt is rounded off and the head has a silver solder dome.

I used 1/2" Allen head bolts to make my contact screws.

I started by clamping the bolt in the chuck of my power drill and used the edge of a triangle file to remove about

1mm of thread from under the head of the bolt while running the drill.

Next I ground the head of the Allen bolt down to give it the same diameter and sloping shape of a contact screw.

Next I tightened 3 hex nuts onto the bolt so that I could turn it around in the drill chuck to cut the 1/2" bolt

down to the required 3/8". I used a fine hacksaw blade to cut down the bolt and I then ran the drill and used

a file to round off the end of the bolt.

The bolt is now ready to be soldered. I spread flux inside the hole of the bolts head.

I estimated the size of solder needed by trial and error and placed a length of it into the hole.

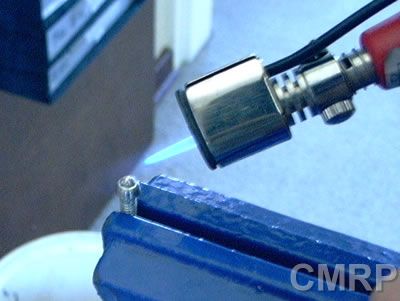

Begin heating the solder with a butane torch.

After a few seconds the solder will collapse and run into the areas spread with flux.

The solder makes a nice dome all by itself. I put the bolt back into the drill chuck and

using fine sandpaper I smoothed off the dome and sanded the dome down a bit if needed.

From Left: Original contact screw, My repro, 1/2" Allen head bolt.

I made seven bolts in 3 hours. The original is on the right.