|

Join

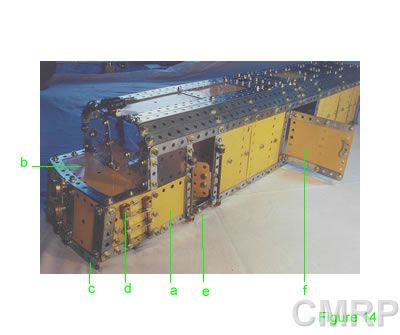

the front with a 2½” x 5½” plate (Fig 14b)

forming the bonnet. It must line up with the front edge

of the sideways 2½” x 4½” plates. Bolt a

curved 5½” strip across the front of the top

plate. The front is made up from a 2½” x

5½” plate (curved slightly).Bolt a 5½”

strip (Fig 14c) across the bottom, spaced one hole down

with fishplates. Use 2½” strips on the edges of

the bonnet plate, side plates and front plate to neaten

up.Bolt ¾” flanged wheels to the front as lights.

I placed LED lights in mine, wired up to the battery box

used to power the motor for the fans.

One hole

from the front, using threaded bosses (Fig 14d) at the

top end, 2” threaded rods create a ladder with two

2½” narrow strips. The side windows are

1½” x 2½” clear plates, held in a frame

made of 2½” narrow strips bolted to the

12½” strip and 2½” x 4½” plate. The

driver doors are two 1½” x 1½” plates

bolted together to form a 2” x 1½” plate. Two

hinges hold the doors on.

A step

is made from angle brackets and a 1½” strip (Fig

14e). Handrail supports on either side of the door are

made up with collars and 3½” threaded rods

locknutted to the rods.

|