PROJECT 5

October 2002 - January 2003

REPAIRING AND RESTORING A 1970'S MECCANO SP3 STEAM ENGINE

Stripping, cleaning and refurbishing

I began by removing the flywheel and piston assembly. I heated up the cylinder with my butane torch, and eventually the piston came out.

Luckily it was not heat seized but it was some sort of hard substance that was causing the bind. Maybe it was some old lubricant that had hardened up over time.

Next I drilled out the pop rivets holding the boiler cover on. I de-soldered the steam pipe entering the steam block with my butane torch and removed the boiler.

I drilled off the firebox and steam block, leaving me with a pile of rusty junk !

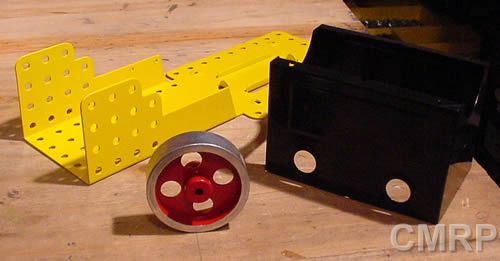

The disassembled motor.

I cleaned all the paint off the flywheel, firebox and base in caustic soda. The flywheel was not rusted, but it was stained badly on the top side of the wheel. I did not want to sand the flywheel because of the fine groves that are present around the diameter of Mamod flywheels, so I used a polishing wheel and Brass polish to remove the stains.

The flywheel polished, masked off and ready for spraying.

I masked off the flywheel and primed and sprayed it post office red.

I sanded the base and with a sanding block and 400, then 800, then 1000 grit sandpaper.

The firebox was not so bad so it got 800 then 1000 grit sandpaper. I then treated the base and firebox with a rust remover.

It was a solution I bought at the hardware store and is called "Rust Remover". I don't know what chemicals are in it, but it works well. It is a clear gel that you brush over the surface and then rub with steel wool. It turns brown quickly from fine rust in the corners and spots difficult to sand.

You rinse it off with running water and keep applying gel and rubbing until the gel stops going brown. You then give it a final rinse in hot water with dishwashing liquid.

The base and firebox before being rust treated. You can see the fine rust in the corners.

I sprayed the base with primer and then with sunshine yellow.

The firebox got sprayed with self priming heat resistant black paint.

The resprayed flywheel, base and firebox.

I used a polishing wheel in my drill to polish the piston, steam block, cylinder, steam pipe, boiler etc... The brass cleaned up very nicely, the metal parts such as the piston shaft and direction lever were rusted. I polished them and the rust was removed and there was slight pitting left on the surface. I did not sand it as I did not want to loose the fine chromed finish and it looked fine anyway at such a small scale.

The boiler was the most difficult. You have to constantly keep on adding fresh "Brasso" or brass polish that you are using. The boiler had a clear lacquer finish on it that was too damaged to keep. I decided not to add a clear lacquer finish to the boiler once it was clean. I reassembled it with the boiler keeping a natural brass finish.

The polished brass.

The cover sanded and polished before being sent off to the electroplaters.

I had the boiler cover chromed by an electroplater. I called around in the yellow pages and I was told to look for a place that does "Decorative chroming". The cost was cheap, about the price of a hamburger meal.

The chromed boiler cover.