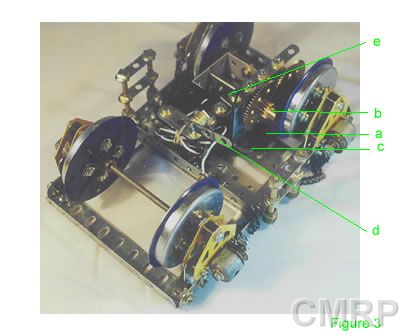

The wheels are built up from a wheel flange (p#137) and a face plate (p#109), spaced with plastic collars and ½” bolts so not to distort the wheel flange. The wheels roll on 4½” rods, spaced away from the inner trunnion with washers.

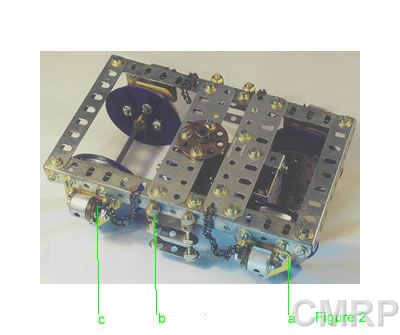

On the outer edge of the trunnions, chimney adaptors are bolted on. 11/8” bolts in the end hole hold a pulley and a piece of chain on as to represent the brake cylinders (Fig 2b).

2” threaded rods carry two 1½” thin strips as steps and are held onto the center of the 7½” angle girder lock nutted to collars (Fig 2c) bolted onto the girder.