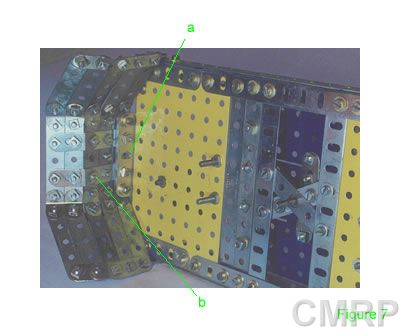

Construct the rear bumper by

stacking six 3½” strips on top of each other,

next to another six 3½” strips joined at the ends

with fish plates and ½” bolts. Lock nut two

tension springs to the top bolts to represent electric

and hydraulic connectors.

A coupling is bolted to the lower 3½”

strips, and angle brackets and obtuse angle brackets

form the coupling.

Using ½” bolts in the top

strips, bolt the bumper to the 1½” angle

girder.

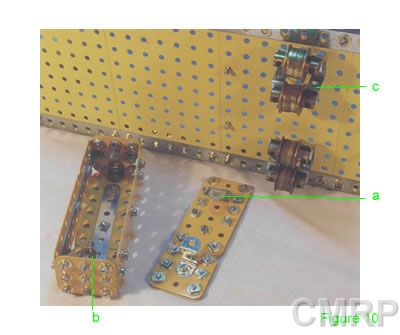

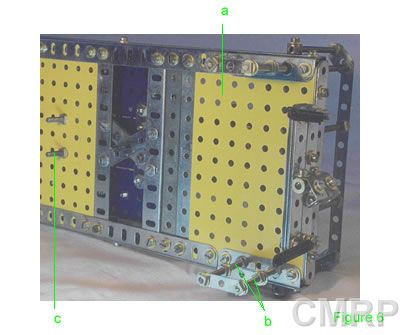

One hole from the rear, lock nut a 2” threaded rod (Fig 6b), and two holes later another 2” rod in the U girder. Lock nut two 1½” narrow strips on to form steps. Do this on both sides.

Note the two ¾” bolts (Fig 6c). They are bolted to the 2½” x 5½” plate to form stops for the bogies. They stop the bogies from spinning 180 degrees when transporting and only allow limited bogie travel left and right.